Electrical faults are among the most common challenges faced by anyone working with wiring systems, whether in vehicles, automation panels, or electronic devices. They arise not only from design errors but also from aging and environmental stress. Over time, these factors weaken joints, loosen fasteners, and create unstable electrical paths that lead to performance issues.

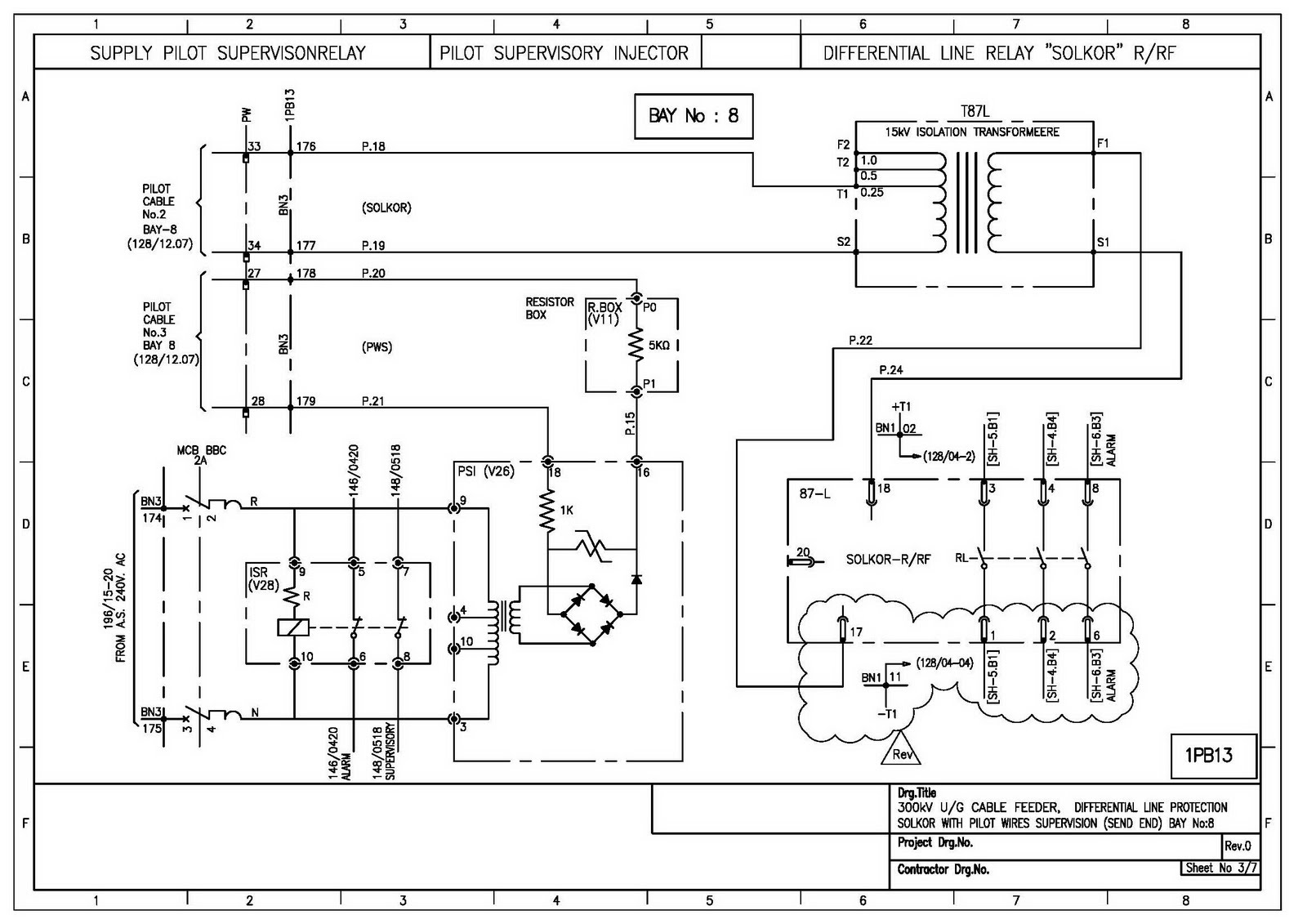

In actual maintenance work, faults rarely appear as simple defects. A loose ground may mimic a bad sensor, a oxidized terminal may cause random resets, and a concealed internal short can disable entire subsystems. Understanding why and how these faults occur forms the core of every repair process. When a circuit fails, the goal is not merely to replace components, but to trace the root cause and restore long-term reliability.

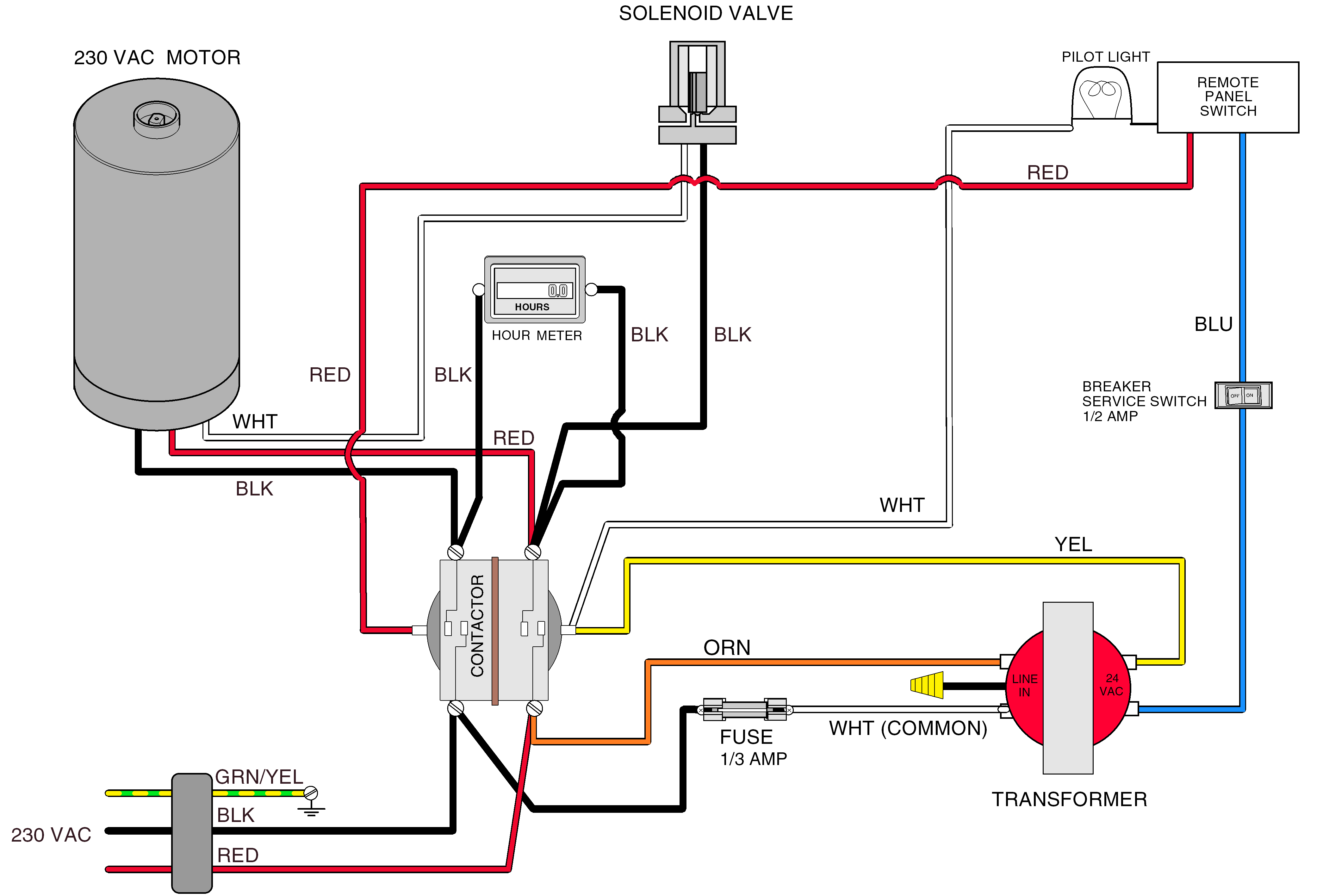

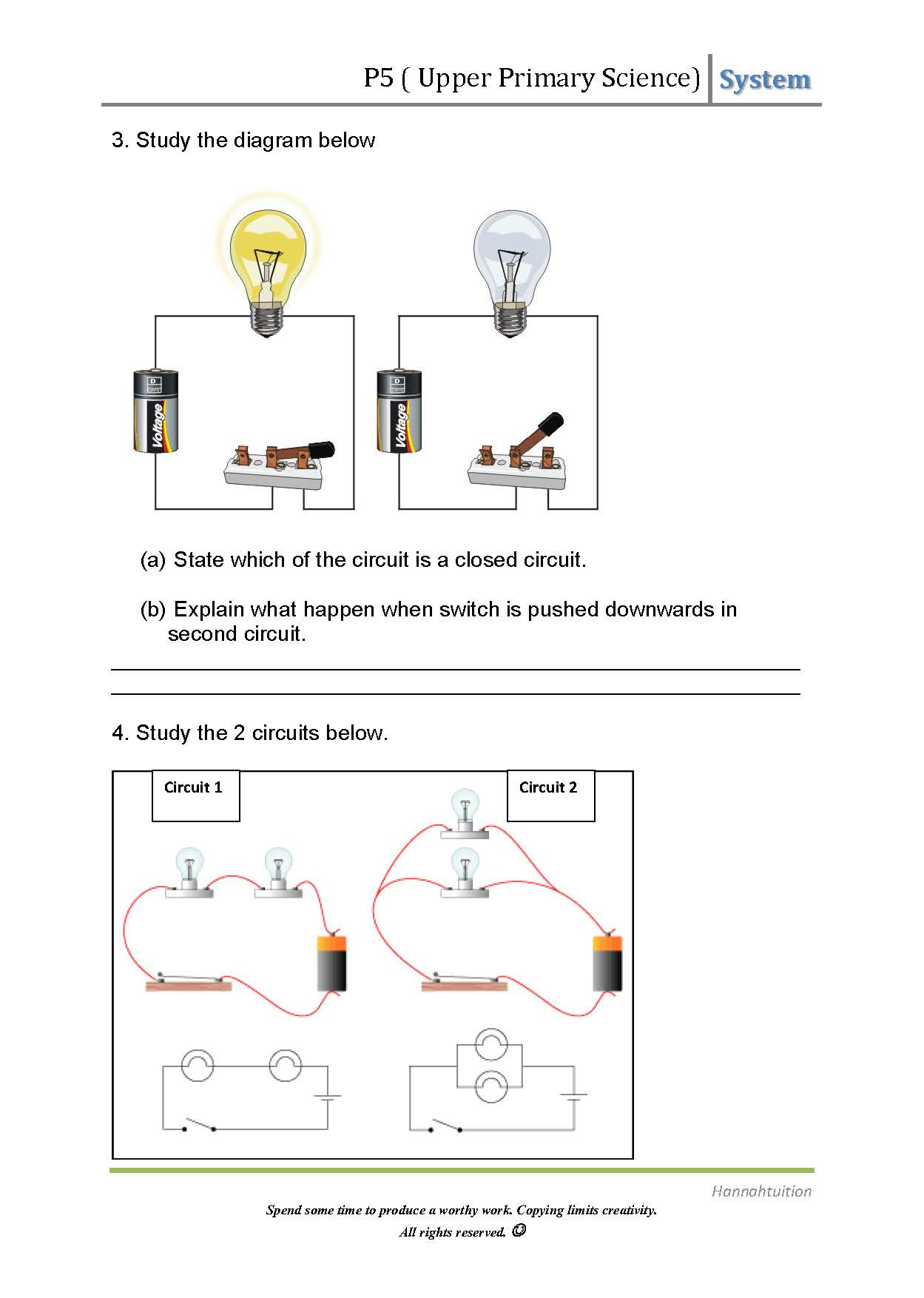

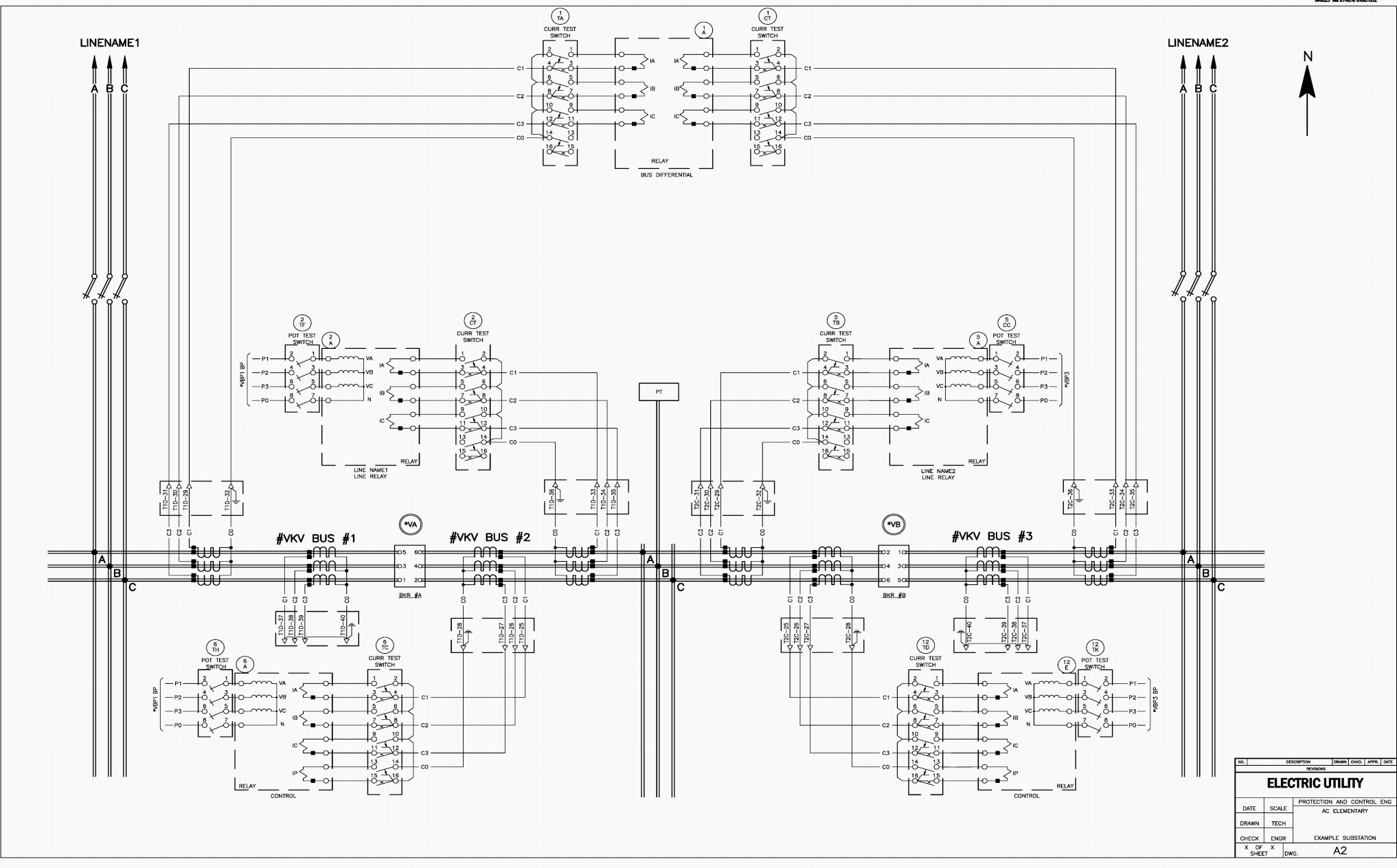

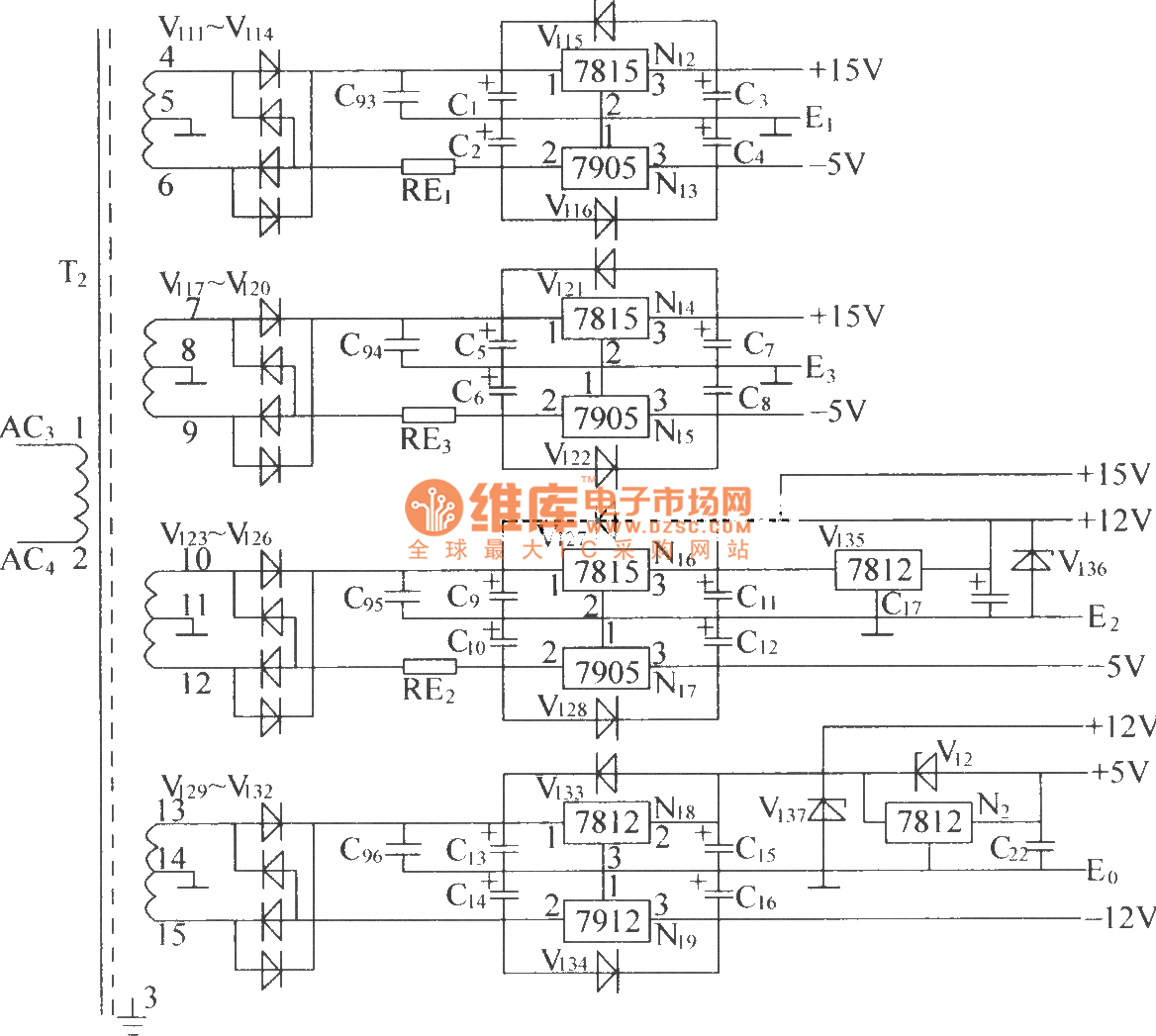

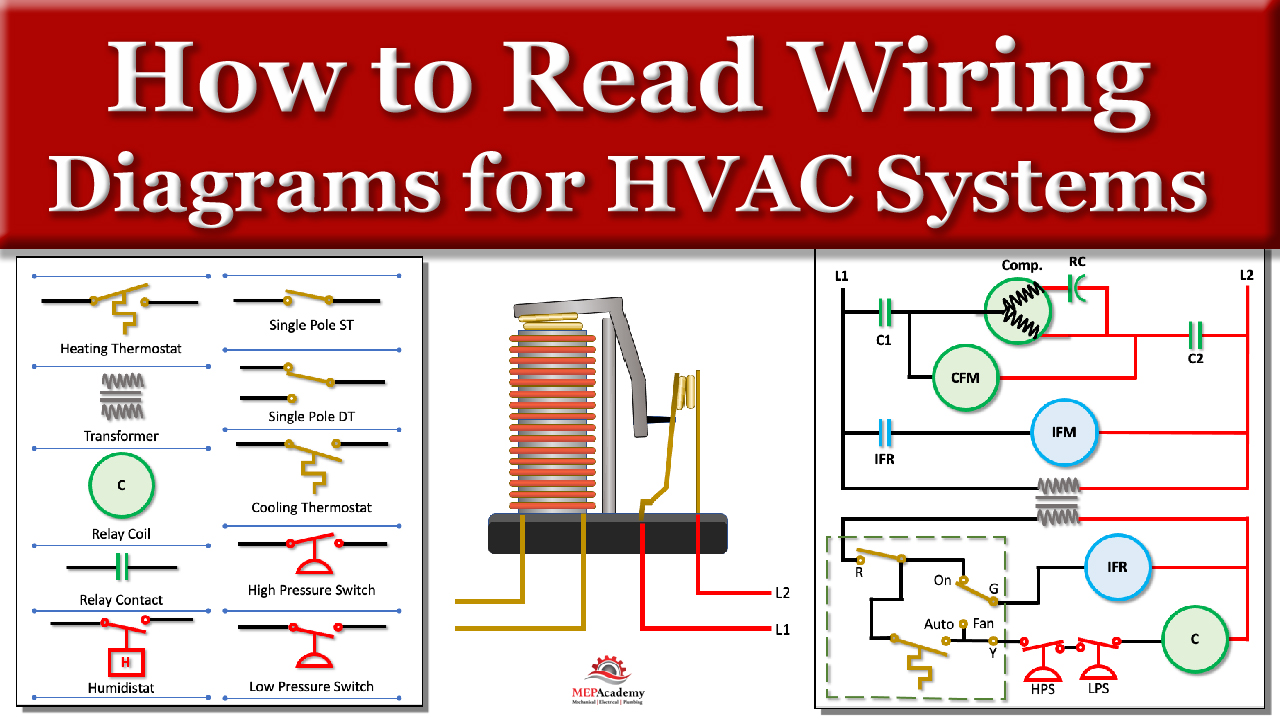

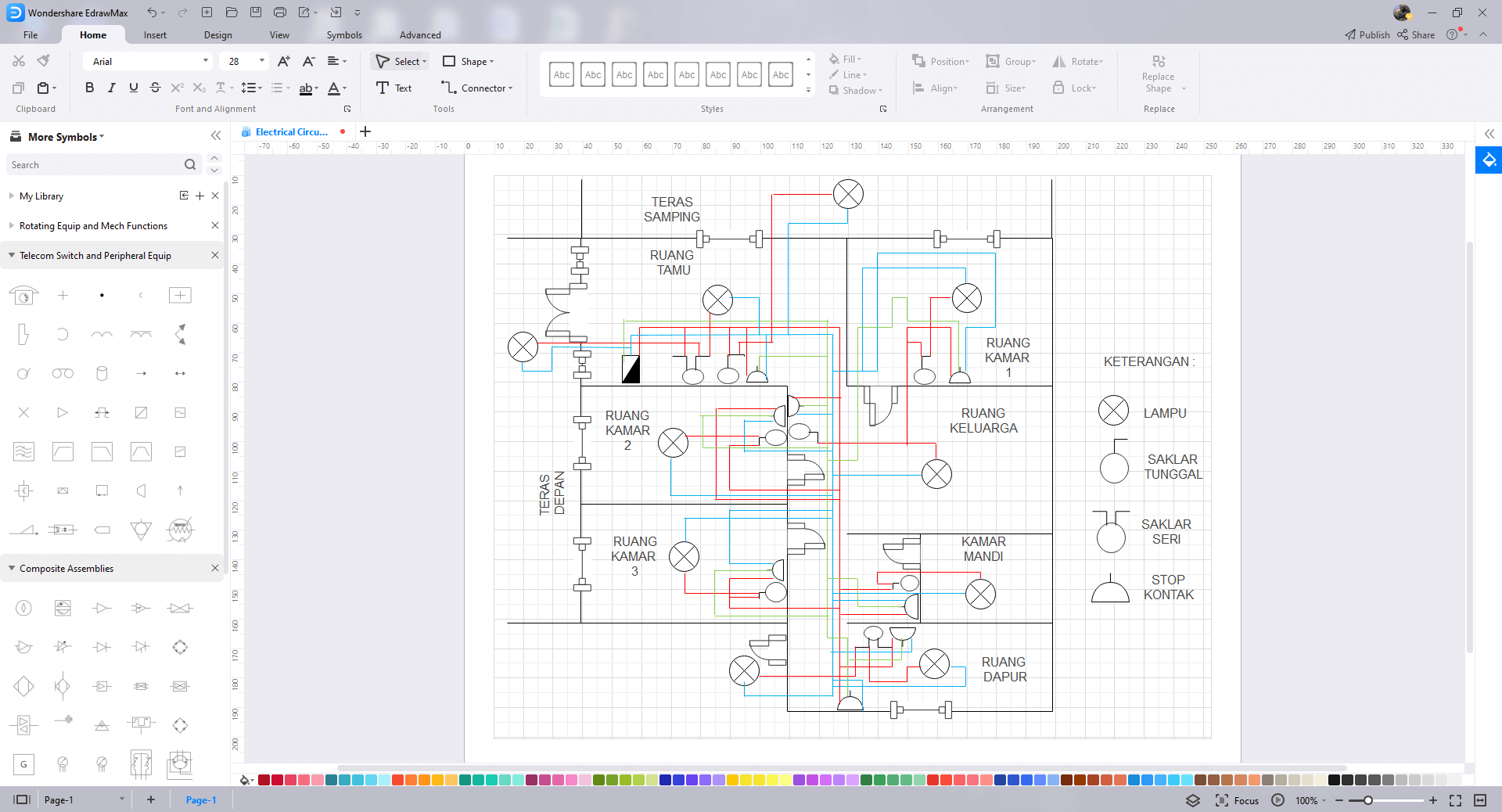

This section introduces the common failure types found in wiring systemsopen circuits, shorts, voltage drops, poor grounding, and corrosionand explains their observable effects. By learning the logic behind each failure type, technicians can analyze real-world signs more effectively. Continuity checks, voltage loss tests, and careful observation form the foundation of this methodical approach, allowing even complex wiring networks to be analyzed systematically.

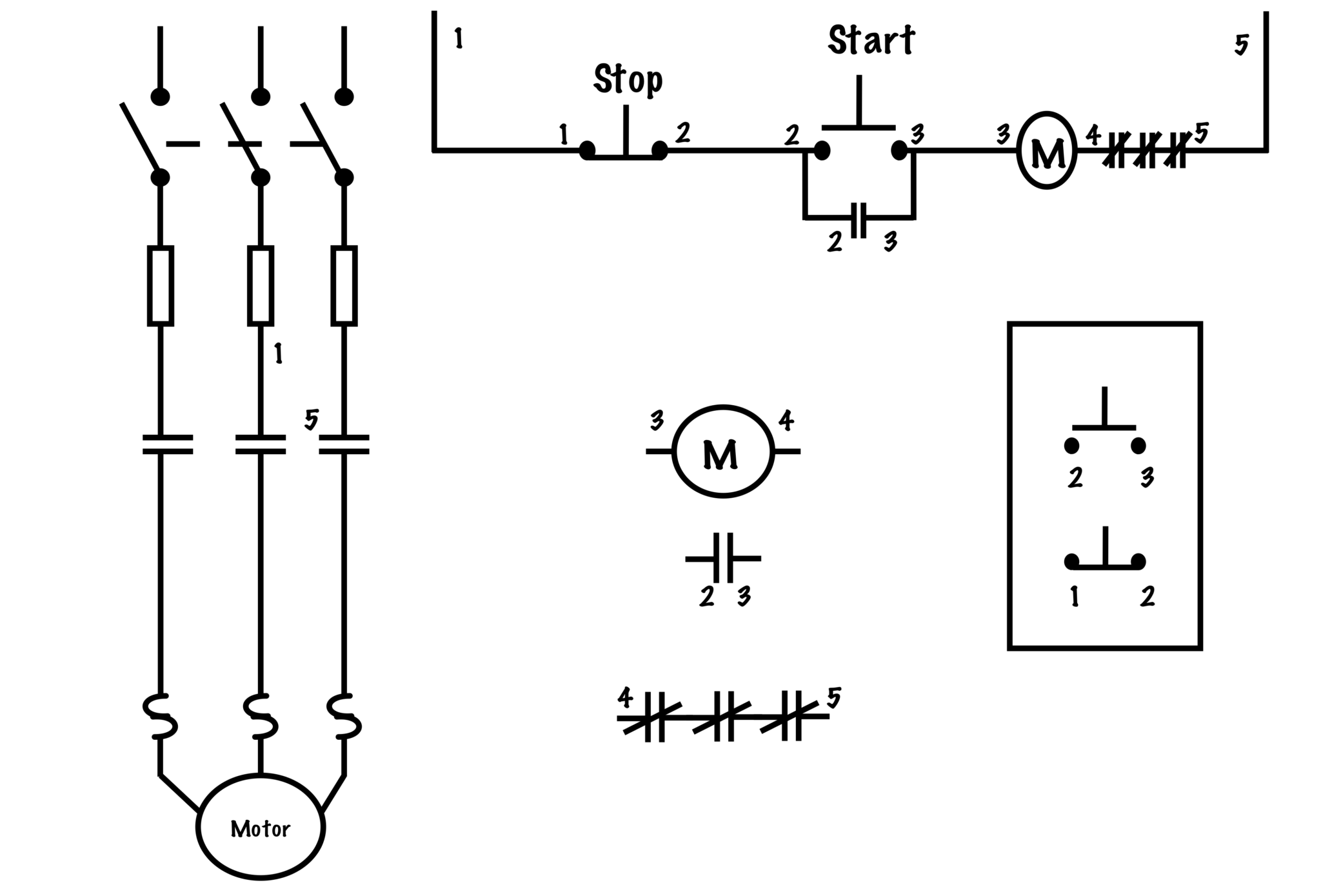

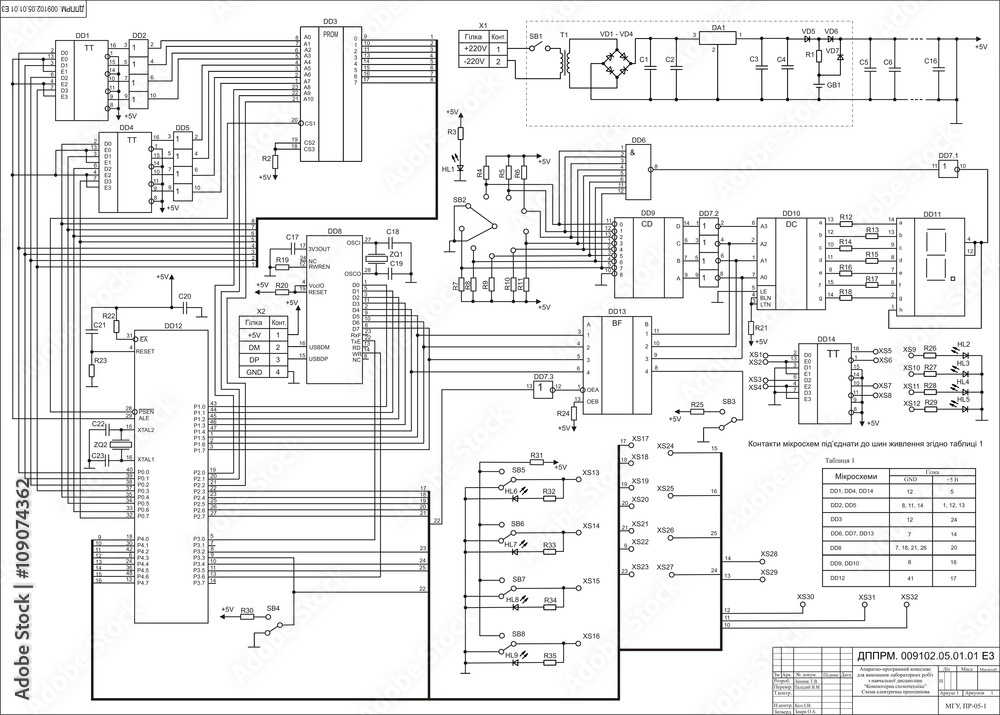

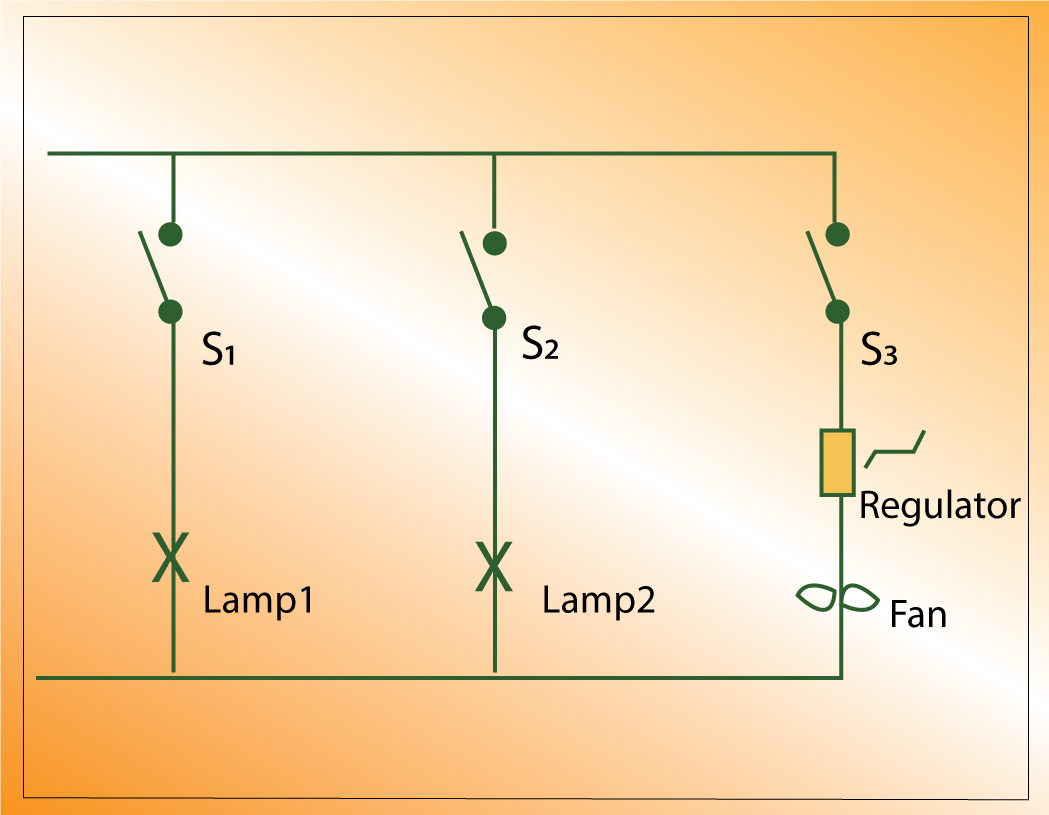

Each fault tells a pattern about current behavior inside the system. A snapped wire leaves an open circuit; damaged insulation lets current escape from intended routes; an oxidized joint adds hidden resistance that creates voltage imbalance. Recognizing these patterns turns flat schematics into living systems with measurable behavior.

In practice, diagnosing faults requires both instrumentation and intuition. Tools such as DMMs, scopes, and current probes provide numbers and traces, but technical judgment and familiarity determine where to measure first and how to interpret readings. Over time, skilled technicians learn to see electrical paths in their mental models, predicting weak points or likely failures even before instruments confirm them.

Throughout this manual, fault diagnosis is treated not as a separate procedure, but as a natural extension of understanding electrical fundamentals. By mastering the core principles of Ohms law, technicians can identify which part of the circuit violates those rules. That insight transforms troubleshooting from trial-and-error into logic-based investigation.

Whether you are repairing automotive harnesses, the same principles apply: follow the current, verify return paths, and let the measurements reveal the truth. Faults are not randomthey follow identifiable laws of resistance and flow. By learning to read that hidden narrative of current, you turn chaos into clarity and bring electrical networks back to life.