As electrical and automation systems become increasingly complex, traditional individual signal cabling can no longer handle the rising volume of signals efficiently. Modern wiring networks therefore rely on communication protocolsdefined sets of rules that determine how devices exchange information. These methods have transformed wiring from simple power and signal links into smart, digital communication infrastructures capable of monitoring, coordination, and diagnostics.

At its essence, a communication protocol defines how data is formatted, transmitted, and interpreted. Rather than each sensor and actuator needing its own cable, multiple devices can share a single communication channel. This drastically reduces wiring complexity while improving scalability and maintenance. The protocol ensures that, even though devices share the same conductors, their messages remain separate and interference-resistant.

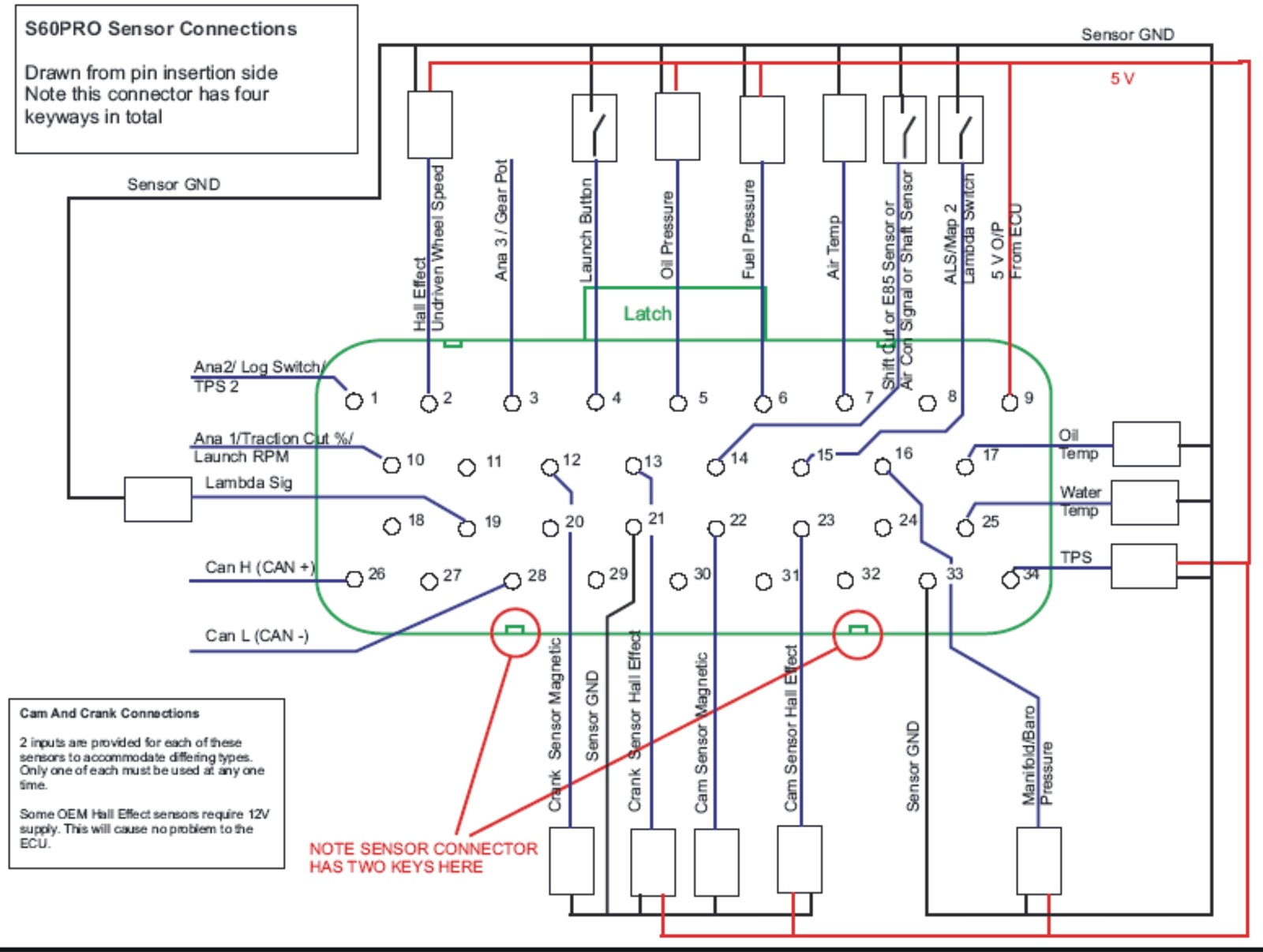

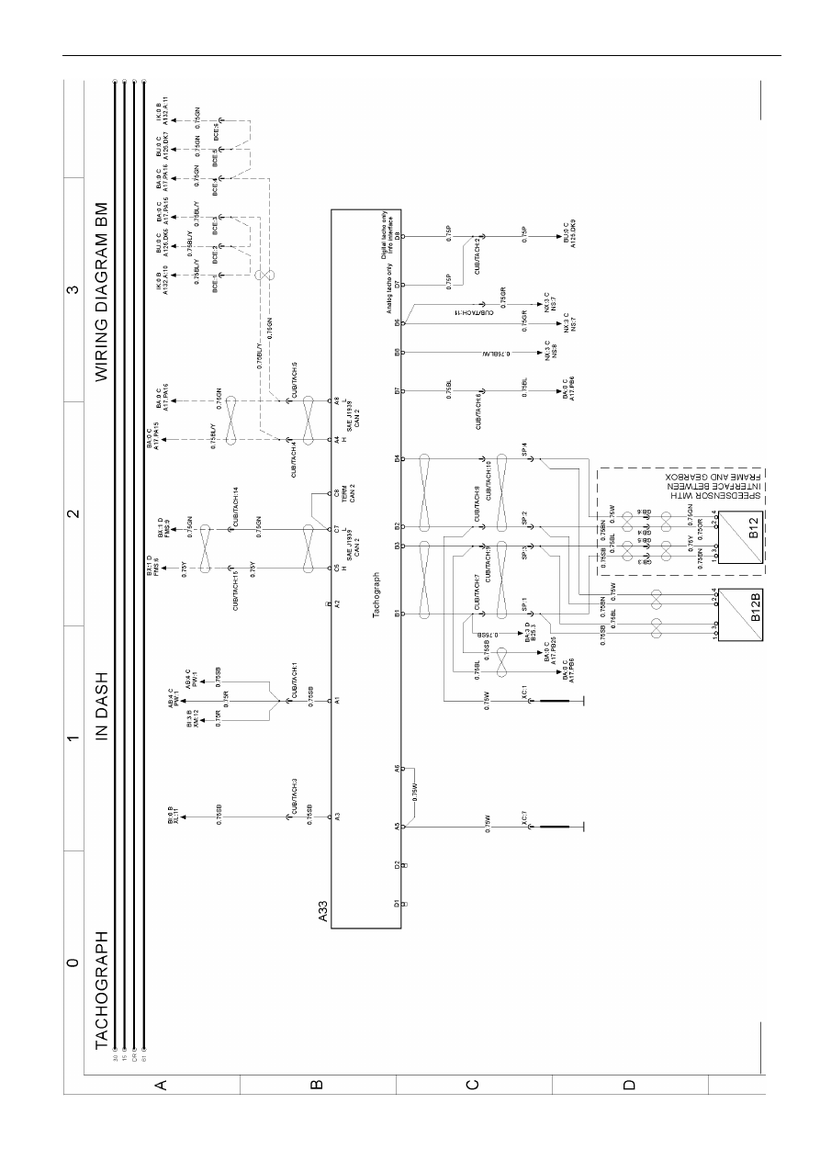

One of the most widespread examples is the Boschs CAN system. Originally developed by Bosch in the 1980s, CAN allows microcontrollers and sensors to communicate without a central host. It uses a decentralized structure where all nodes can transmit and listen simultaneously. Data priority is managed by message ID, ensuring that high-priority datasuch as real-time control parametersalways takes precedence. Its robustness and noise immunity make it ideal for high-interference installations.

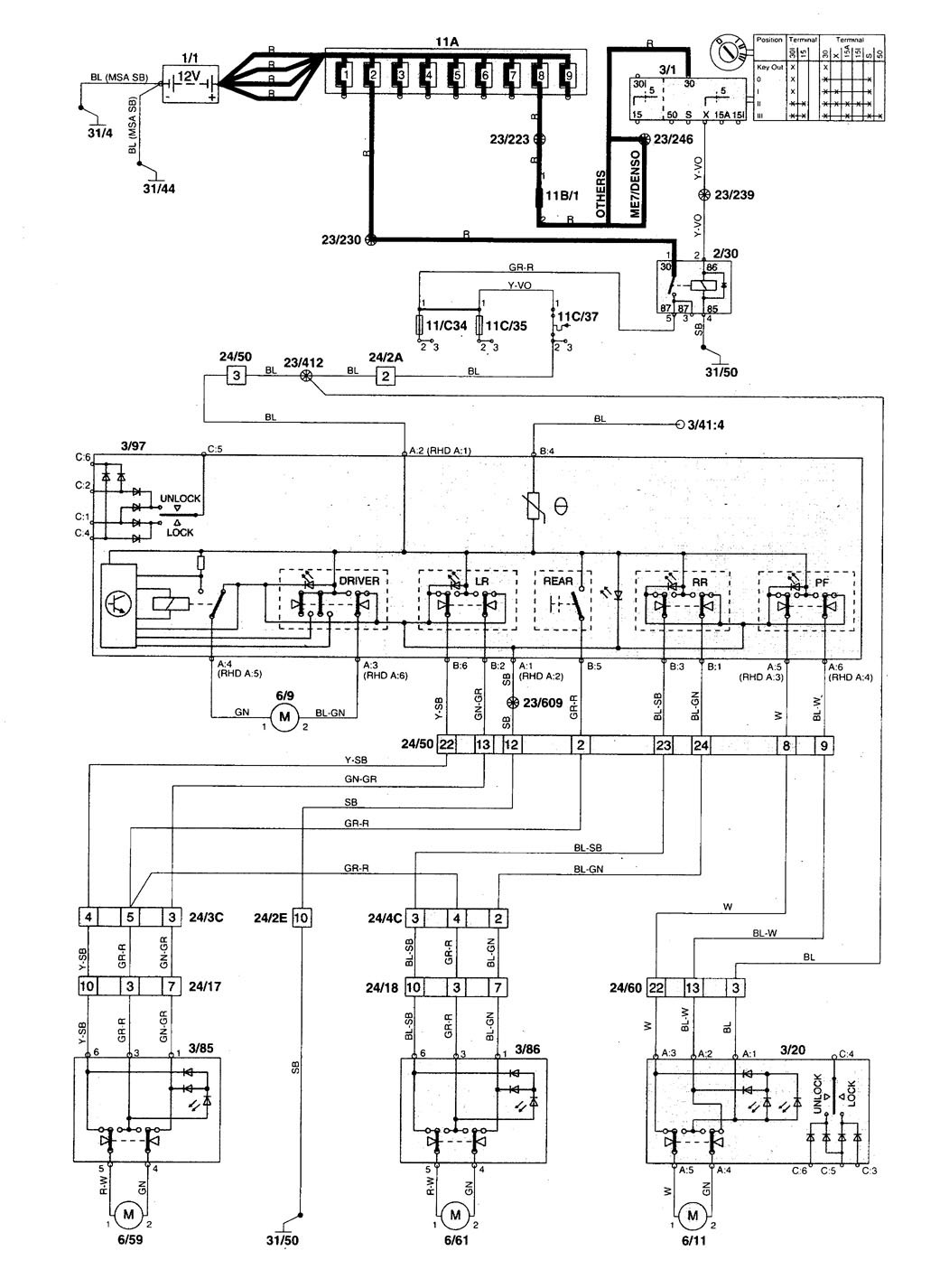

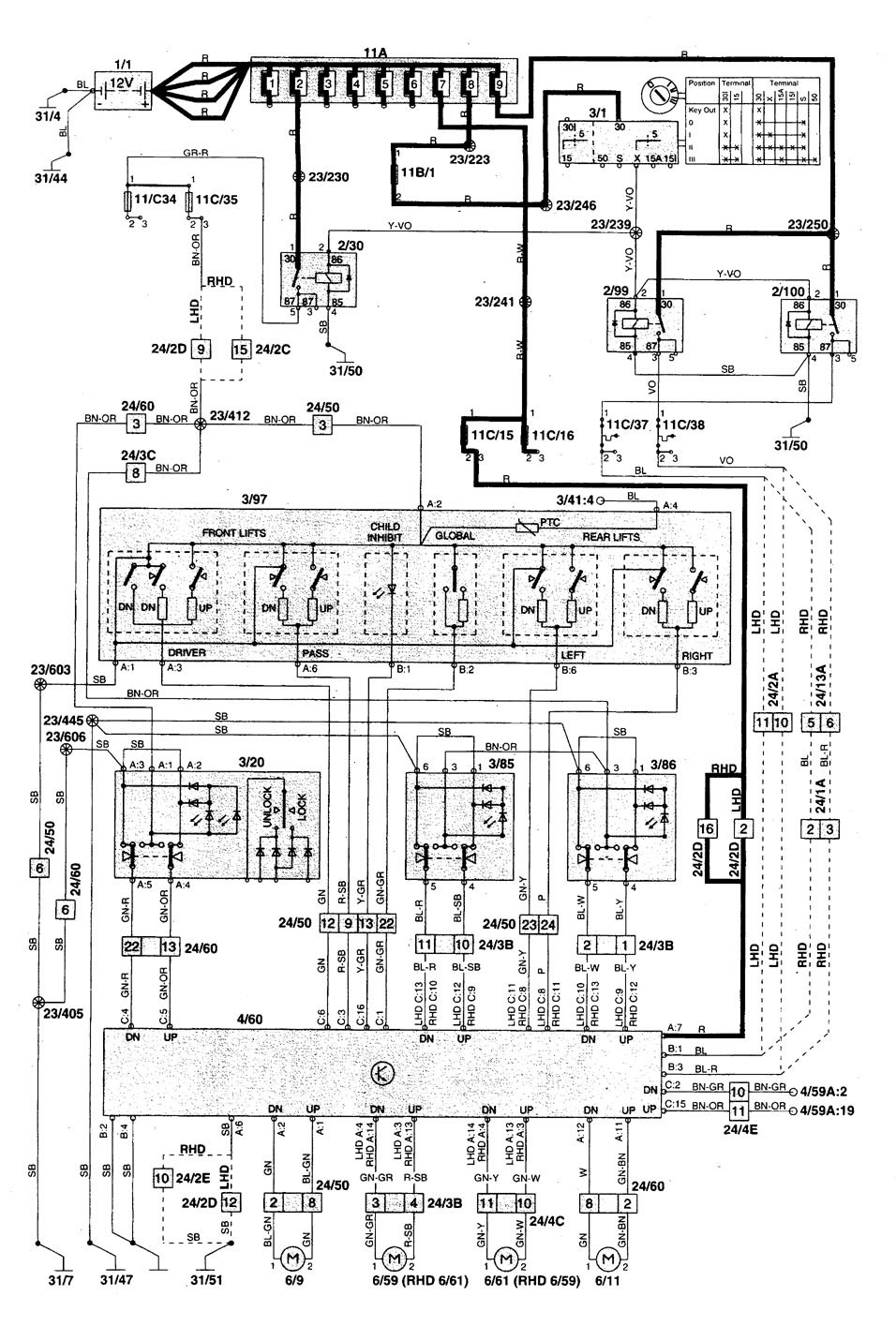

Low-cost Local Interconnect Network serves as a simplified companion to CAN. While CAN handles complex real-time control, LIN connects less demanding components such as window switches, mirrors, or HVAC sensors. Operating under a master-slave scheme, one central node manages the communication timing of all others. LINs simplicity and low cost make it an ideal choice for auxiliary circuits that complement high-speed CAN networks.

In industrial automation, fieldbus protocols like Modbus/Profibus dominate. Modbusamong the oldest communication systemsis valued for its openness and simplicity. It transmits data via serial lines like RS-485 and remains popular because of its wide support across PLCs, sensors, and HMIs. Process Field Bus, meanwhile, was designed for industrial precision. It employs deterministic communication to coordinate hundreds of devices on a single network, offering both factory automation and process control.

As Ethernet became more accessible, industries migrated toward industrial Ethernet protocols such as EtherCAT, PROFINET, and Modbus TCP. These technologies combine network versatility with deterministic timing needed for real-time control. For example, EtherCAT processes data **on the fly** as it passes through each node, reducing latency and achieving sub-millisecond precision. Such efficiency makes it ideal for servo systems and high-precision manufacturing.

For smaller distributed systems, RS-485 remains a fundamental wiring layer. Unlike single-link communication, RS-485 supports multiple devices on a twisted-pair network running for hundreds of meters. Many industrial communication layers like Modbus RTU rely on RS-485 for its simplicity, noise resistance, and range.

The emergence of IoT-enabled sensors has given rise to lightweight, efficient communication protocols. IO-Link bridges simple sensors with digital networks, enabling the transmission of readings plus metadata through standard 3-wire cables. At higher layers, MQTT and OPC UA facilitate edge and cloud interoperability, crucial for Industry 4.0.

Beyond the protocol rules, **wiring practices** determine signal quality. minimized EMI layout and structured grounding prevent data corruption. Differential signalingused in CAN and RS-485ensures balanced transmission by sending opposite signals that neutralize interference. Conversely, bad installation practices can cause communication instability.

Modern networks integrate redundancy and diagnostics. Many systems include redundant lines that automatically take over if one fails. Devices also feature self-diagnostics, reporting communication errors, voltage drops, or latency issues. Maintenance teams can access this data remotely, reducing downtime and improving operational continuity.

In the era of intelligent manufacturing, communication protocols are the lifeline of automation. They let controllers, machines, and sensors share not only signals but also diagnostics and intent. Through standardized communication, systems can analyze performance and prevent failure.

By mastering industrial data networks, engineers move beyond connecting wiresthey enable machines to speak across entire ecosystems. Every byte transmitted becomes a command, response, or safeguard. Understanding that conversation is the key to intelligent design, and it defines what makes the next generation of electrical engineering.