Modern electrical and electronic systems depend on sophisticated methods of energy management and safety that go far beyond basic copper circuits and mechanical relays. As engineering advances, so do the expectations for reliability, speed, and accuracy in delivering electrical energy to every load. From factories and embedded devices, understanding modern power-control logic is crucial for designing and maintaining resilient electrical networks under all conditions.

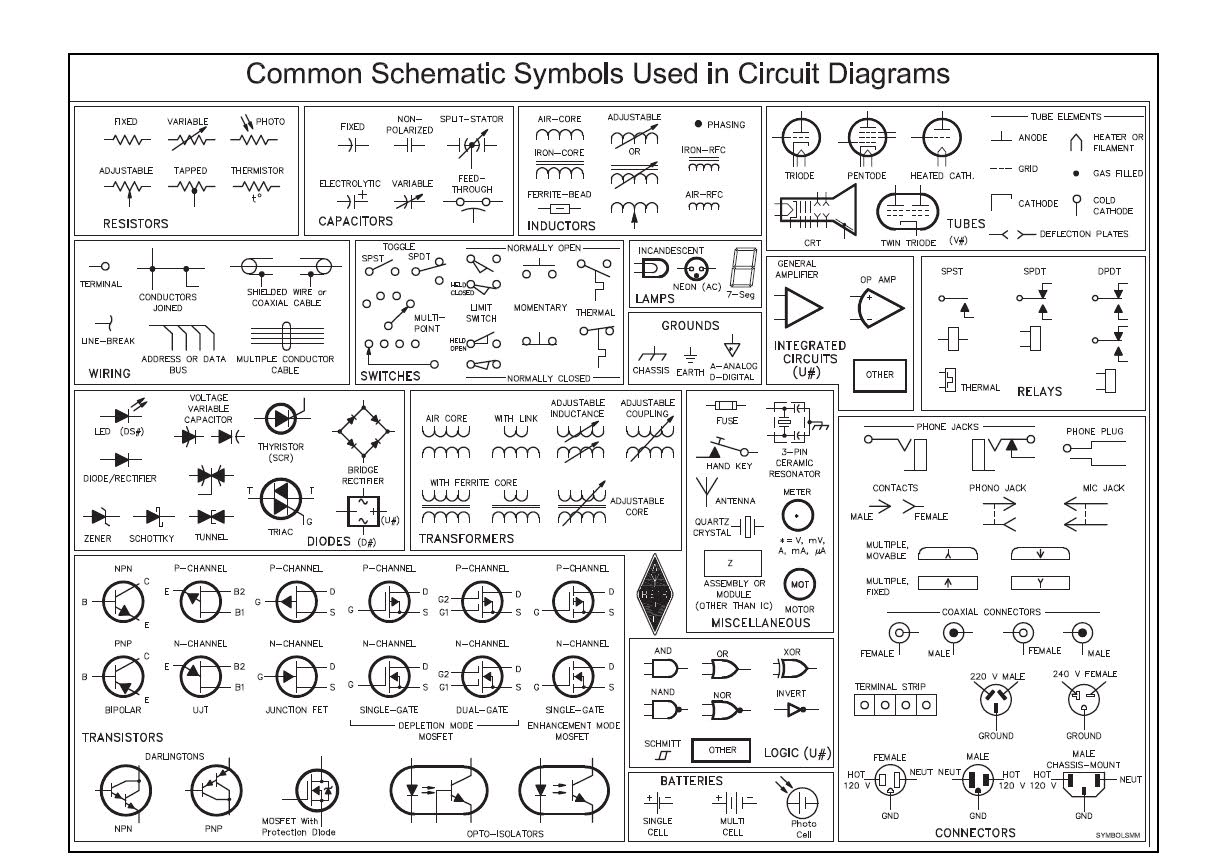

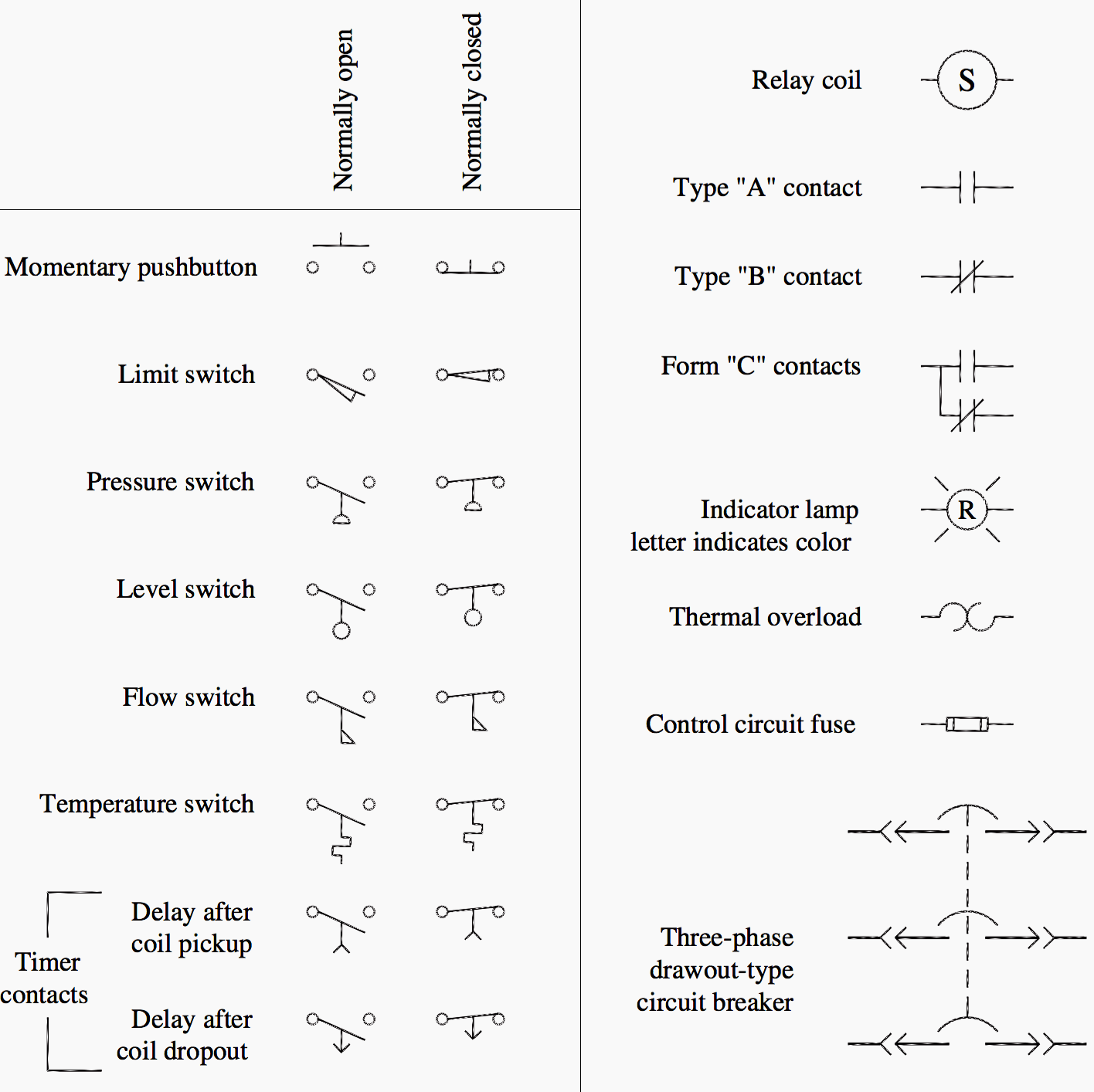

At its core, power distribution is the discipline of channeling energy from a single source to multiple destinations without excessive loss or imbalance. Traditional systems relied on electromechanical devices to manage power. While reliable for decades, these methods fail when facing microprocessor-controlled devices. To meet new operational standards, engineers now employ electronic circuit breakers, digital fuses and smart sensors, and adaptive electronic protection that respond instantly to load variations.

An electronic fuse (e-fuse) performs the same protective role as a conventional one but with precision control. Instead of melting metal, it uses sensors to cut current instantly, often within microseconds. Many e-fuses reconnect after the fault clears, eliminating downtime. Advanced versions also report data via industrial communication buses, sharing real-time current, voltage, and event logs for deeper insight.

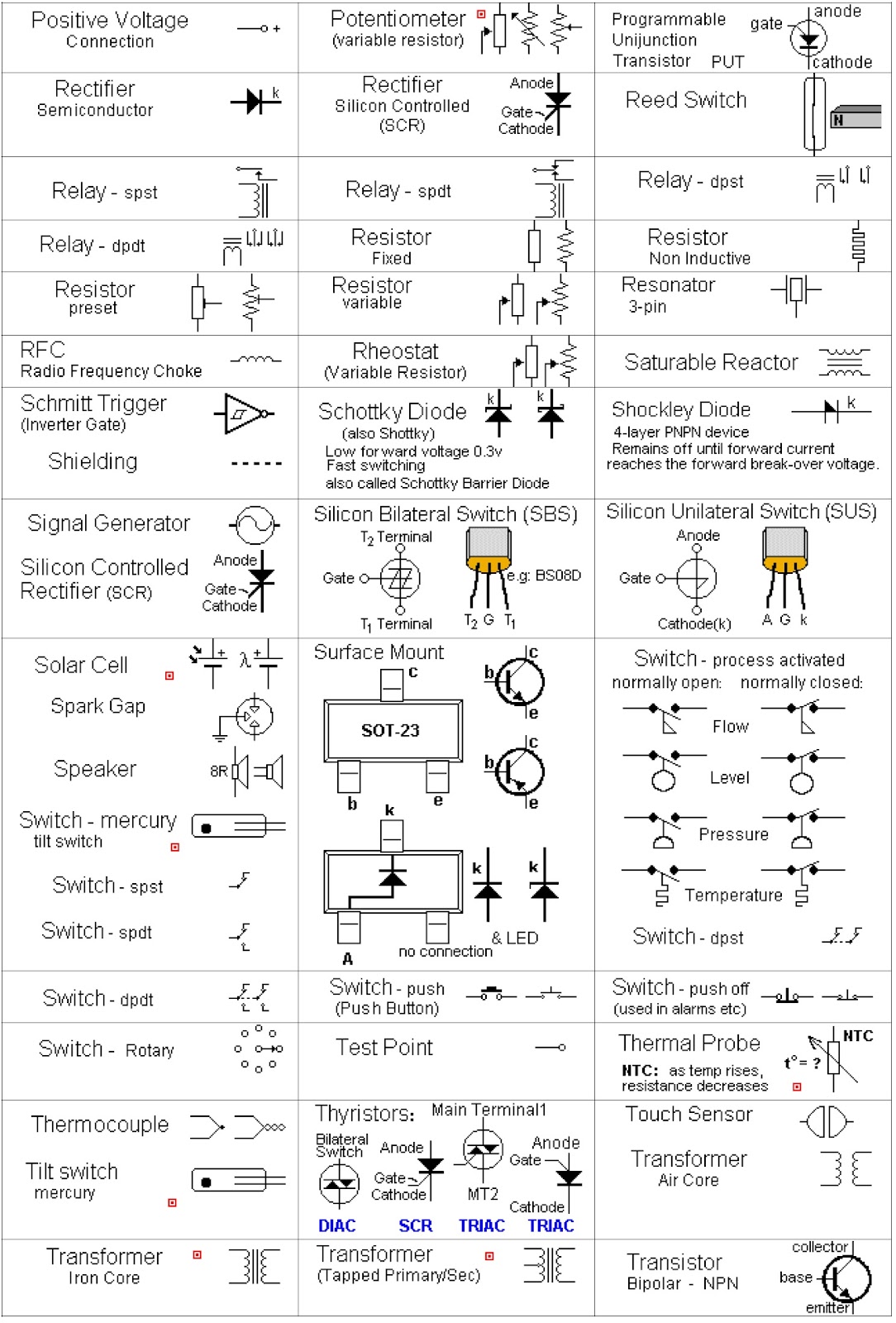

Solid-state relays (SSRs) have replaced mechanical contactors in many industrial and vehicular applications. They switch faster, create minimal EMI, and suffer virtually zero arc damage. In environments subject to vibration, dust, or high temperature, solid-state components surpass mechanical types. However, they introduce heat management requirements, since semiconductors generate heat under heavy load. Engineers mitigate this through careful design and cooling integration.

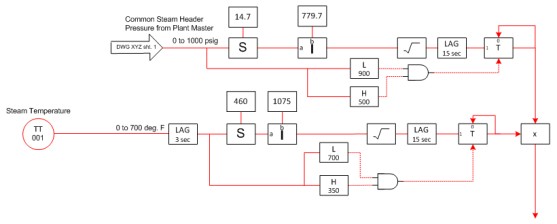

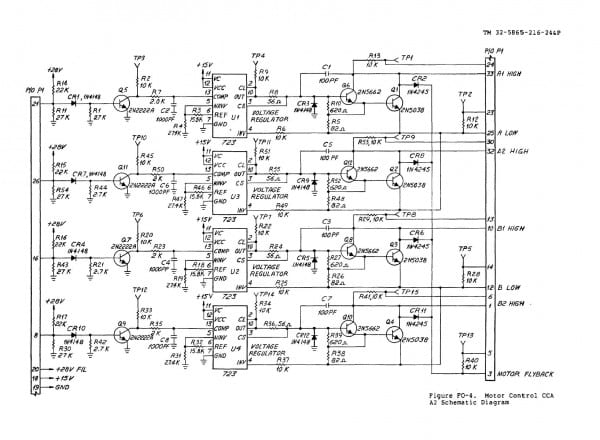

A well-structured power distribution architecture separates main, auxiliary, and control subsystems. Main feeders use busbars or heavy cables, branching into localized subnets protected by distributed e-fuse modules. Each node balances between sensitivity and continuity: too tolerant and faults persist; too tight, and circuits shut down unnecessarily. Smart systems use self-adjusting trip curves that distinguish temporary surges from actual faults.

Grounding and return-path design form the invisible backbone of modern power networks. Multiple groundssignal, power, and chassismust coexist harmoniously. Poor grounding causes noise, voltage drift, or false readings. To prevent this, engineers implement controlled bonding networks, using braided conductors, copper straps, or bus plates that maintain stability under vibration. ECUs and monitors now track potential differences in real time to detect early degradation or corrosion.

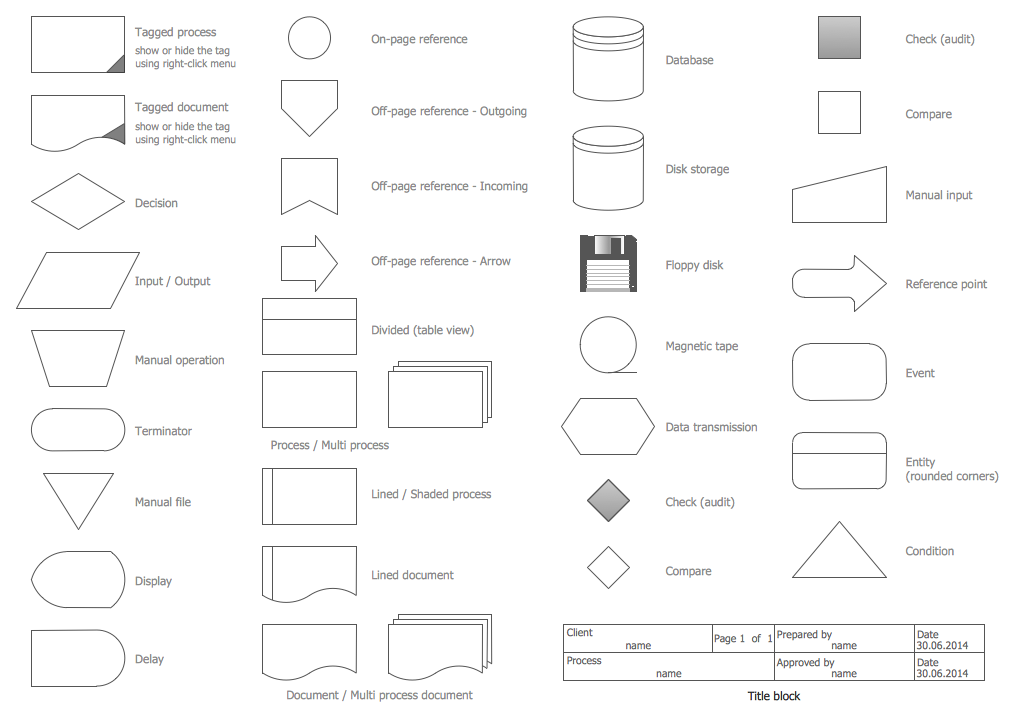

The fusion of electronics and power systems marks a major shift in energy control. Microcontrollers within electronic fuse panels measure real-time loads, log data, and control logic distribution. This intelligence enables data-driven reliability, where systems detect circuits nearing overload. Supervisory software visualizes current paths, fuse status, and system health across entire installations.

Protection components themselves have evolved. In addition to e-fuses, engineers employ self-resetting thermistors and magnetic-trip protection. Polyfuses self-limit current, resetting automatically after coolingideal for space-constrained electronics. Current-limiting breakers trip fast enough to cap energy before conductors overheat. Selection depends on load type and criticality.

Modern simulation tools enable engineers to model faults and heat flow before hardware is built. By analyzing electrical and thermal interactions, they ensure safe power margins under all conditions. These digital models lead to predictable, safe systems.

From a maintenance view, smart distribution simplifies repairs and inspections. Built-in sensors and logs record overcurrent events, pinpoint which circuit tripped, and allow virtual reconnection without physical access. This is invaluable in vehicles, aircraft, and offshore systems, reducing service time and cost.

Despite new technologies, the principles remain timeless: electricity must flow efficiently, safely, and controllably. Whether through copper conductors or silicon switches, each design must protect the circuit, isolate faults instantly, and document configurations accurately.

In the bigger picture, advanced distribution and modern fusing techniques represent the future of electrical safety. They show how mechanical design, electronics, and software now merge into intelligent energy networks that are not only protected but also self-aware and self-correcting. Through these innovations, engineers achieve both performance and protection, ensuring that energy continues to power the world with precision.