The grounding network is the unseen protector of modern power systems. It equalizes potentials, shields equipment, and safeguards operators. Yet despite its importance, grounding is often neglected or poorly implemented, leading to noise interference, hidden faults, and dangerous failures. A sound grounding strategy forms the foundation of electrical safety and reliability in any modern facility.

### **Purpose of Grounding**

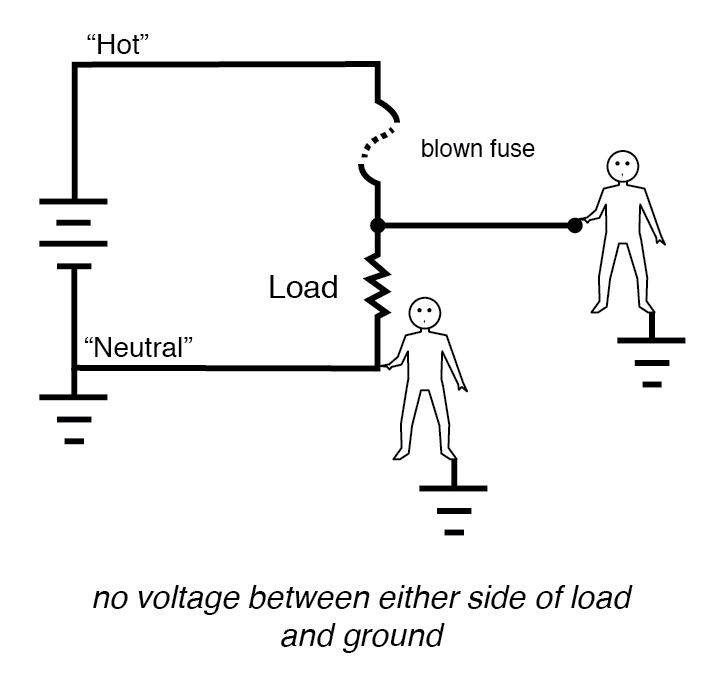

At its simplest, grounding creates a common electrical reference among all metal parts. Without a shared earth reference, voltage can wander across dangerous levels, resulting in shock, malfunction, or insulation stress. By connecting metal frames, enclosures, and reference nodes to the ground, excess current from short circuits, lightning, or static discharge flows safely to ground instead of through sensitive circuits or operators.

Grounding fulfills three primary roles:

1. **Personnel Protection:** Limits shock energy and ensures operator protection.

2. **Equipment Protection:** Diverts fault current away from devices.

3. **Signal Integrity:** Minimizes noise and interference in control and communication circuits.

### **Types of Grounding Systems**

Different environments and networks demand specific grounding methods:

- **TN Systems (Terra Neutral):** Common in commercial facilities, where neutral is grounded at the source and protective earth is run throughout. Variants such as separate or combined neutral-earth layouts define how conductors share or split current paths.

- **TT Systems:** Each installation has its own earth electrode, isolated from the supply neutral. This design reduces fault propagation but depends on sensitive protection.

- **IT Systems:** The source floats or uses resistance to earth, allowing critical uptime under insulation failure. Found in hospitals, ships, or critical manufacturing.

Selection depends on the trade-off between protection, continuity, and maintenance effort.

### **Design Principles**

An effective grounding system begins with properly engineered earth grids and rods. Target resistance is typically under 5 ohms, though mission-critical sites may require 1 ohm or less. Soil type, moisture, and temperature directly affect performance; engineers often optimize soil resistance with treatments or salts.

**Bonding** links all metallic partsframes, conduits, trays, and structuresinto a single equipotential system. Bonding conductors must be short, thick, and smooth, with clean terminations to prevent corrosion. Mesh grounding works for large, fault-tolerant grids.

**Ground loops** occur when multiple earth paths create circulating currents, causing voltage offset. The cure is proper analog/digital ground separation joined at one node. For high-frequency circuits, use wide copper straps or ground planes.

### **System Stability and Noise Control**

A solid grounding design enhances both safety and signal quality. Power electronics, VFDs, and communication lines generate high-frequency interference that couples into nearby wiring. Shielding and grounding work in synergy to neutralize unwanted radiation. Use 360° terminations for braid grounds, and single-ended grounding for low-frequency control lines.

Integration with lightning protection is essential. Lightning currents and transient surges must have a short path to ground. Without low inductance, energy reflects into circuits, damaging electronics.

### **Testing and Maintenance**

Even the best earthing setups age and weaken. Corrosion, loosening, and soil drying increase resistance. Periodic testing using ground continuity and impedance analyzers ensures reliability and safety.

In critical sitestelecom, energy, and industrial plantsmonitoring is often continuous. Ground-potential sensors and alarms detect rising resistance or abnormal voltages. Maintenance teams log results, trend data, and adjust proactively.

### **Integration with Modern Design**

Todays smart systems merge grounding with digital analytics. Sensors in switchgear, busbars, and panels record fault currents, impedance, and ground potential. Software then visualizes earthing conditions, helping engineers locate weak points instantly.

As renewables and distributed power sources expand, grounding strategies evolve. Battery banks and DC buses require special grounding to manage floating potentials. International standards such as IEC 62109 and IEEE 1547 define how new technologies maintain stability and protection.

### **Conclusion**

Grounding is not an afterthought; its the electrical systems silent stabilizer. Proper design ensures fault energy finds its way to earth, keeping machines operational and operators protected. When maintained with testing and documentation, grounding transforms from a static component into a living safety system.